Samsung Plans to Mass Produce Flexible Mobile-Device Screens

Fujifilm Tech Makes Low Cost 15TB Discs Possible, Expecting 1TB in 2015

Samsung Plans to Mass Produce Flexible Mobile-Device Screens

As the battle for dominance in the smartphone and tablet-computer market intensifies, South Korean conglomerate Samsung is pushing ahead with plans to start mass production of displays using plastic rather than glass, a move that will make mobile devices unbreakable, lighter and bendable.

Samsung's display unit, Samsung Display Co., is in the last phase of development of so-called flexible displays for mobile devices, which are expected to be released in the first half of next year, a person familiar with the situation said.

It is still unclear when devices using the technology will be available commercially, and Samsung declined to comment on how much it is investing in the displays.

Samsung's flexible displays will incorporate OLEDs, a display technology that the South Korean company is already using in its smartphones and television sets. OLEDs are thin and can be put on flexible material such as plastic or metal foil. By using plastic rather than glass, they make the displays more durable and light.

Flexible OLEDs have been in the development phase for many years, and companies including Sony Corp. of Japan and LG Display Co. of South Korea also have launched prototypes. However, manufacturers haven't been able to commercialize them or use them in devices due to technological barriers in mass production. Samsung hopes it will be first to bring the product to the market.

The vice president of Samsung's display unit, Lee Chang-hoon, said the company is currently sampling the displays with a few customers. Mr. Lee said the release date of a new product based on flexible displays hasn't been determined yet.

Source: The Wall Street Journal

Fujifilm Tech Makes Low Cost 15TB Discs Possible, Expecting 1TB in 2015

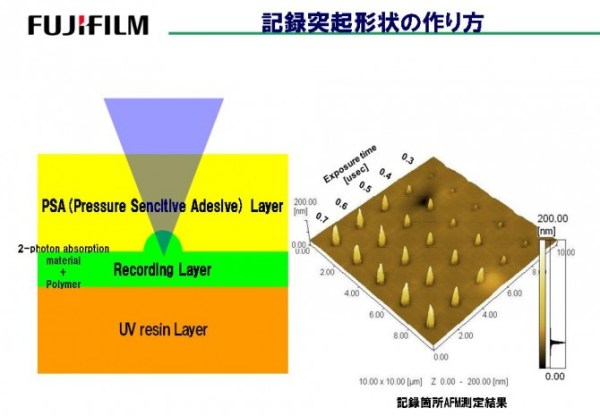

Fujifilm has announced that it has developed a new method for recording to optical discs, claiming the technology makes it possible to store 25 GB of data per layer. That the same amount of data per layer as Blu-ray, however the new technology makes it possible to have 20 layers per side of a disc. A double sided disc with 20 layers on each side would make it possible to store 1 TB of data on the disc.

The company hopes to bring those discs to the market in 2015 and hopes that with further improvements it will be able to use 100 layers. This means that it should be possible to store 15 TB of data on a single disc.

The technology makes use of two photon absorption to generate heat. The major thing it seems to make possible is to change a part of the disc, with a certain depth irreversible with a very precise laser. The data can be read by detecting the change of the amount of light reflected on the interface between the recording layer and the adhesive material.

The discs should be low cost as the disc can be made at once, where for Blu-ray discs several actions have to be taken to for each layer on the disc. According to Fujifilm it takes 147 seconds to create a four layer BD disc, while it takes 58 seconds to form a eight layer discs using their technology.

Source: MyCE

Write a comment below. No registration needed!