|

||

|

||

| ||

First microprocessors appeared over 30 years ago. The microelectronic technology made a step forward, and while in the beginning a computer was affordable only for elite, today it's our "integral part". But together with this transition the computer industry acquired a lot of problems. No secret that high-performance processors heat up much, i.e. dissipate a lot of thermal power. And a modern high-speed silicon heart of a computer can't do without additional cooling devices. A problem of obtaning the optimal working temperature is very urgent today - it is a corner-stone in creation of a reliable, ergonomic and high-performance computer system. The widespread and universally recognized processor cooling means is a cooler (heat-exchange apparatus of forced air-cooling). Usually they combine a metallinc finned plate (heatsink) and an air pump (fan); it supports a processor's working temperature within the permissible frames providing its correct and reliable functioning. Well, let's take a closer look at such devices. HeatsinkHeatsink is a device that facilitates heat exchange between a processor and environment. A surface area of a processor's die is usually rather small (several square centimeters today) and is not enough for effective carrying off of thermal power of dozens of Watts. Thanks to its finned surface a heatsink installed on a processor makes its area of contact with environment much greater, and, thus, it makes heat exchange much more intensive and a working temperature much lower.Thermal resistance of a heatsink relative to a surface of a processor's die is its fundamental technical characteristic; it estimates its cooling effectiveness. Thermal resistance has the following formula: Rt = (Tc - Ta)/Ph, Rt - thermal resistance of heatsink,

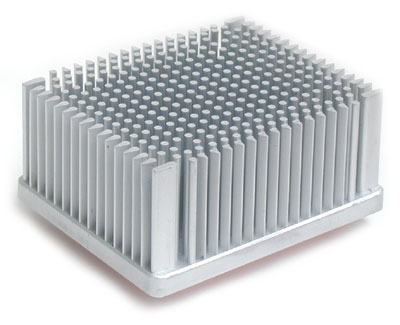

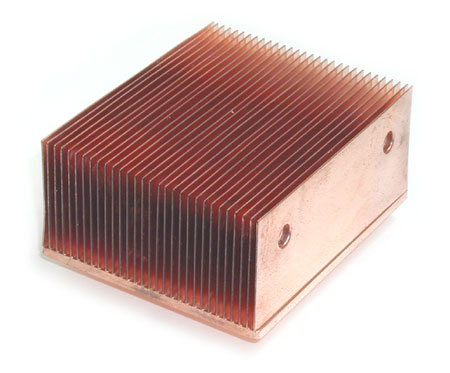

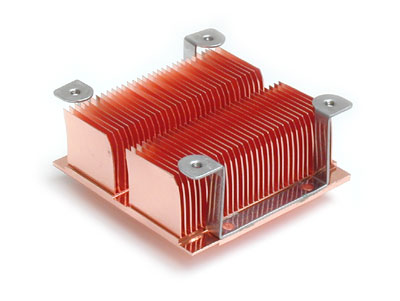

Thermal resistance is measured in °C/W. It shows increase of a die' temeprature relative to temperature inside the system unit with thermal power carried off via a given heatsink installed on the processor. Let's take the VIA Eden platform as an example. A typical thermal resistance of a processor's heatsink is 6°C/W, a typical thermal processor's power is 3 W and a typical temperature inside a system unit is 50°C. The product of the heatsink thermal resistance and processor's thermal power is 18°C. Now we know that the temperature of the die's surface is higher than the temperature inside the system unit by 18°C and it will be maintained at 68°C. This temperature complies with the "medical" standards for the VIA Eden ESP processors, and we have nothing to be worried about. Now let's consider one more example. If we take a heatsink from VIA Eden ESP and couple it with the AMD Athlon XP processor whose thermal power is 40-60 W, the result will be quite sad: the processor's temerature will reach 300°C and more which will cause its death from "heat stroke". Such thermal power needs a heatsink (or even a normal cooler) with much lower thermal resistance so that the processor's temeprature doesn't exceed 75-90°C. There is a clear principle of thermal resistance: the less, the better. If we know it, we can easily find out whether we can use a certain heatsink (or a normal cooler) in our certain conditions. Also, we can avoid mistakes which can cause failure of a computer system or of your wallet :). Thermal resistance of a heatsink depends not only on a finned surface but also on its design and technology of production. At present the market offers 5 archetypes of heatsinks involved in mass production. Extruded heatsinks. The cheapest and most popular on the market; they are made of aluminum. The method of extrusion allows for making a complicated finned surface and good heat-removing properties.      FansModern processors need cooling devices with thermal resistance as low as possible. Today even the most advanced heatsinks are not able to cope with this task: in case of free air convection, i.e. when an air mass speed is low (for example, vapor over an asphalt road in a hot summer day), the rated thermal effectiveness of heatsink is not enough for maintaning an acceptable working temperature of a processor. There is the only way to cardinally reduce heatsink's thermal resistance - to ventilate it thoroughly (i.e. to create conditions of forced convection of a heat carrier (air)). That is why almost every processor's heatsink is equipped with a fan which blows through its inter-fin space.Today processor's coolers mostly use axial fans which form an air flow in a direction parallel to an impellar's axis of rotation.  How can we know whether a fan is good or bad? What are its technical characteristics and working parameters? Let's see! First of all, a fundamental characteristic of any fan is its performance, i.e. the value that shows a volumetric air flow rate (cubic feet per minute, CFM). The higher the fan's performance, the more effectively it pumps air through a heatsink reducing its thermal resistance. A typical performance is 10-80 CFM. Secondly, an impellar's speed is a very important characteristic of a fan (rotations per minute, RPM). The faster the impellar rotates, the higher the fan's performance. A typical speed is 1500 - 7000 rpm. Finally, dimensions should be accounted for as well. As a rule, the bigger the fan, the higher its performance. The most popular dimensions are 60x60x15 mm, 60x60x20 mm, 60x60x25 mm, 70x70x15 mm, 80x80x25 mm. As far as working parameters are concerned, a noise level and a service life are the most considerable among them. A noise level is measured in decibels and shows how loud noise can be in subjective perception. A noise level can vary from 20 to 50 dBA. A human considers a fan quiet if its noise level doesn't exceed 30-35 dBA. At last, a service life of a fan is measured in thousands of hours and it objectively shows how reliable and durable a certain fan is. An acual service life of fans based on sleeve bearings doesn't exceed 10,000-15,000 hours and of those based on ball bearings - 40,000-50,000 hours. So, that's all for today. Next time we will disassemble fans and take

a closer look at some technical details.

Vitaly Krinitsin (vit@ixbt.com)

Write a comment below. No registration needed!

|

Platform · Video · Multimedia · Mobile · Other || About us & Privacy policy · Twitter · Facebook Copyright © Byrds Research & Publishing, Ltd., 1997–2011. All rights reserved. |