|

||

|

||

| ||

GlacialTech, a Taiwanese company, was founded in June 2001, however, it already has a solid research-and-production base and advanced technologies. Despite its young age the company is moving quickly toward the certification of production according to the ISO 9001 standard. It took GlacialTech half a year to have hearts of computer enthusiasts, careful overclockers and product-managers conquered in more than 30 companies of Europe, Asia and America. Today we are going to look at two the most advanced models of Socket A GlacialTech coolers - Igloo 2310 and Igloo 2400, examine their operating abilities, thermal efficiency and noise characteristics. Key featuresLet's start with the Igloo 2310.

This model has an extrusion aluminum heatsink of 70x60x35 mm and a standard fan of 60x60x20 mm. If you look closer you will notice several quite interesting details. It has fins of trapezoid cross section with the base being 0.8 mm thick and the vertex 0.3 mm think. Such construction allows saving on material, reducing the weight of the cooler and improving thermal efficiency of the fin (and, thus, the cooler). A heat-flow density along the axis of a usual fin of the rectangular cross section gradually reduces which decreases heat-exchange intensity and overall efficiency of the cooler. At the same time, a heat-flow density along the axis of a fin of the same height but of the trapezoid cross section remains constant and close to the maximum. The heat-exchange intensity remains the same, and the efficiency is higher than in case of a usual fin. Besides, the fins are different in height (25mm and 30mm fins take turns).

It's done to decrease the overall flow resistance of the heatsink. From the aerodynamical standpoint such construction has the same effect as a step-like one (fins in the center are higher). But from the standpoint of thermal effectiveness the former is better according to the experiments conducted by GlacialTech. The third peculiarity is that the fan is shifted to the front part of the heatsink.

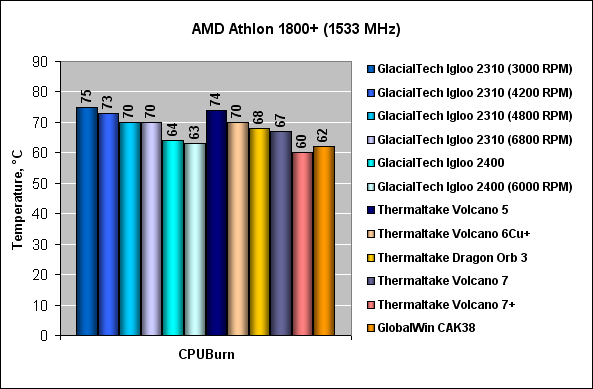

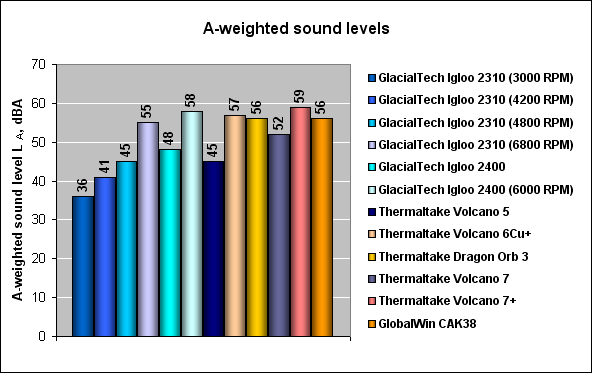

When the heatsink is located right under the fan a certain dead zone is formed; here a flow rate is very low and is determined primarily by recirculations in interfin channels. As a result, the central part of the heatsink doesn't work effectively. It's possible to avoid the dead zone by using a powerful fan with a high volumetric flow rate and static pressure: the intensity of recirculations will be greater and a flow rate will be higher in the central part. But remember that air is quite warm in those recirculations, that is why thermal efficiency doesn't grow up much. Besides, it makes a noise level much greater. The off-center fan changes an air flowing pattern; the dead zone becomes much smaller which improves the overall efficiency of the cooler. Thus, having quite a weak fan (3000 rpm) and a low noise level this cooler competes successfully against very famous coolers. Our tests showed that the Igloo 2310 falls behind the Volcano 5 only by 1°C, but it's quieter by 10 dBA! In case of a 4800 rpm fan (such configuration is available for OEM companies) the Igloo 2310 comes very close to the Volcano 6Cu+ with the noise difference again of 10 dBA. Now let's turn to the Igloo 2400.

This model has a more sizeable heatsink (83x64x35 mm) and a more powerful fan of 5000 rpm (70x70x15 mm). It's based on the same principles - fins have of the trapezoid cross section (0.8 mm think in base and 0.3 mm in vertex) alternate in height, and the fan is off-centered. Taking into account a larger size, a larger number of fins (28 against 25 of the Igloo 2310), the most optimal heatsink configuration and a much more powerful fan (42 CFM against 13 CFM of the Igloo 2310), I assume that the Igloo 2400 is able to compete against very cool models. In our tests this cooler outperforms such monsters as Dragon Orb 3 and Volcano 7. There are only two coolers which are able to stand against it - the CAK38 from GlobalWin and Volcano 7+ from Thermaltake.

The developers of the Igloo 2400 were able to create a product which keeps up with expensive copper heatsinks based on the skived fin technology (Volcano 7+), but at the same time this new-comer is cheaper and quieter. Well, the stereotype that only copper and a high-speed fan are worth the candle is proved to be inconsistent. One must know how to work both with aluminum and with copper. InstallationAs you know, AMD sets quite strong requirements for dimensions, weight, fastening strength and other parameters of coolers for Socket A processors (see AMD Thermal, Mechanical, and Chassis Cooling Design Guide). The developers of the Igloo 2310 and Igloo 2400 tried to meets them entirely. Thus, the Igloo 2310 is of 70x60x55 mm (the maximum size can be 80x60x60 mm), 230 g (out of possible 300 g) and a fastening strength is 4.4 kg (out of possible 5.3 kg). The only issue is the fan's rated consumption (13 CFM against minimal 16 CFM). However, the test shows that even with such a weak fan the Igloo 2310 doesn't yield to models equipped with fans of 25-30 CFM. The Igloo 2400 also meets these requirements (just except the dimensions): 83x64x55 mm, 260 g, 4.5 kg and 42 CFM. The most important parameters of the cooler as far as installation is concerned are weight and fastening strength. These two parameters are closely concerned with each other: to provide a strong and uniform contact of the heatsink and a processor core the strength must be approx 12-15 times more than the cooler's weight. This is a real problem for developers, because at 450 g the cooler gets over the limiting 5.3 kg. Weakening won't help here because the hold-down isn't going to be efficient and it can result in edge loads which are very dangerous for mechanical integrity of the CPU core. There are two way-outs: to ignore AMD's requirements and to increase the strength up to 10-11 kg (the socket won't stand more), or to make the cooler lighter. The engineers of GlacialTech chose the second way: the Igloo 2310 and Igloo 2400 are built on light heatsinks and have the optimal and safe fastening strength. The clip of the Igloo 2310 is tool free.

The clip's handle is rather wide. It's located at 2.5 cm above the heatsink's base, that is why even if there are several capacitors too close to the socket they won't cause any problems in course of mounting/demounting of the cooler. The clip has 4 mounting holes instead of usual two. It makes possible to unload fixing teeth of the socket (1.1 kg for each) and reduces probability of unfastening of the cooler if the teeth are damaged. The clip of the Igloo 2400 is also tool free.

Although this clip is located lower (2 cm above the mounting holes), there are no problems either. But this has only two mounting holes. Installation of the Igloo 2310 and Igloo 2400 must be flawless onto Socket A boards from brand-name companies which follow the AMD's requirements of the prohibited area's size (an area around the socket where elements of the surface mounting are lacking or they are not higher than specified). But I can't guarantee that with budget models of Socket A or Socket 370 boards. At last, the Igloo 2310 and Igloo 2400 have an effective preinstalled thermal interface which is ST700 silvery thermal grease from Highland Electronics (containing 5% silver oxide and 25% aluminum oxide). This thermal grease doesn't yield to Alsil-3 and has excellent physical-chemical properties. TestsLet's start with stress tests of the fans. The Everflow R126020DL model (3000 rpm, comes in the retail version of the Igloo 2310) was able to withstand all extreme modes: it worked stably at the increased and reduced voltage without considerable heating up or vibration. The Everflow R126020DH (4200 rpm) and Everflow R126020DU (4800 rpm) which can't be installed by a user's request into the Igloo 2310 also worked well, but the R126020DU did warm up a little at the increased voltage. The Everflow R127015DU (5000 rpm coming in the Igloo 2400) made no problems either. All fans could stand a long stoppage of the fan: during 24 h they didn't heat up much. The electromechanical part revealed that the bearings are of high quality, the shaft-bearing gap corresponds to the norm, the grease quality is good, as well as the mounting quality. Now let's take a look at the temperature measurement results. But before note that our cooler testing technique has undergone some changes. First of all, we changed the test system. Earlier we used the Intel platform for Socket A coolers (as the AMD platform hadn't correct means of temperature monitoring), now such coolers are tested on the AMD's one with the Athlon XP processor. After we checked the temperature monitoring of several Socket A boards we chose the D1289 model from Fujitsu Siemens Computers. Temperature is monitored by the NE1617A chip from Maxim Integrated Products located very close to the socket. Due to such position all errors caused by too long lines of the processor's thermo diode and the monitoring chip or by too high noise level of these lines are almost lacking. It makes measurements more accurate and allows comparing objectively thermal effectiveness of coolers. And we don't use anymore the typical user environment mode because most of Socket A boards do not allows the processor switch to the reduced power consumption state (Stop Grant), and it consumes almost maximum power all the time. In these conditions the results of the typical user environment mode do not differ much from the CPUBurn one. And it's unjustified to use the former mode. The CPUBurn mode was also changed a little. The experiment showed that results of the shortened tests (less time and a smaller number of attempts) turned out to be identical to those of full tests. That is why we decided to optimize the CPUBurn mode (to simplify the test procedure without quality losses). Now the test consists of 4 attempts (2-3 h each) and the ambient temperature is maintained constant at 32-33°C (such temperature is typical of quality cases with a good ventilation system). The result processing procedure remains the same. So, the test system configuration is the following:

The burnk7 utility from the CPUBurn suite is used to model a thermal load close to the maximum, and the System Guard utility from Fijitsu Siemens Computers is used to control temperature. Test results

Notes: Here we used the ST700

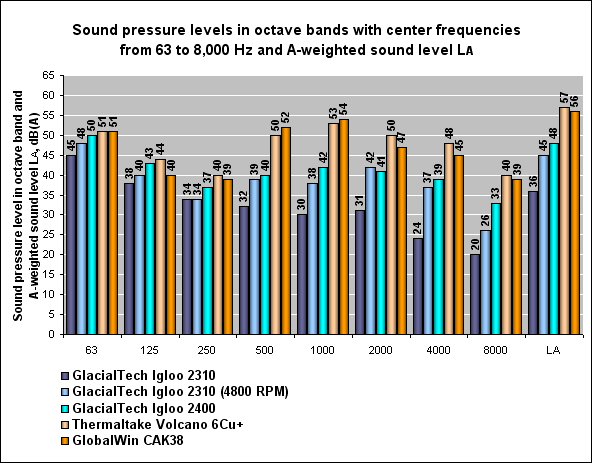

thermal grease. The developers of the Igloo 2310 and Igloo 2400 assure that the parameters of these two coolers are not only advanced but also correlated with construction of the fan. The fan and the heatsink form a single whole, and installation of another even more powerful fan doesn't improve much thermal effectiveness. We decided to check it. The most efficient configuration of the Igloo 2310 is its OEM version with the Everflow R126020DU fan (4800 rpm, 23 CFM). We installed other, much more powerful fan - Delta Electronics AFB0612EH (6800 rpm, 38 CFM) and... didn't get any performance boost! Then we took the TT7025A fan (6000 rpm, 49 CFM) from the Volcano 7+ cooler and tested it with the Igloo 2400. Again, no performance gain: the difference between it and the original Igloo 2400 was just 1°C. Well, we can see that the Igloo 2310 and Igloo 2400 models are really very optimal as far as effectiveness/noise ratio is concerned. And at last here are noise measurement results.

Note: The background noise level is 25 dBa ConclusionToday the GlacialTech Igloo 2310 cooler is an ideal solution for budget and standard systems on the AMD Duron, Athlon and Athlon XP (clocked up to 1533 MHz). In such parameters as thermal effectiveness, noise level, quality of mounting and of fans it has no equal in its category and sometimes even among more expensive coolers. The GlacialTech Igloo 2400 is a very advanced overclocker-meant product. It suits all modern high-performance systems on the Athlon XP. Besides, it's one of the best models as far as effectiveness/noise and effectiveness/price ratios are concerned. In closing I must note that GlacialTech has coolers

not only for Socket A processors. There are models designed also

for Socket 478. Two such models (Igloo 4200/4300) are currently

being tested.

Write a comment below. No registration needed!

|

Platform · Video · Multimedia · Mobile · Other || About us & Privacy policy · Twitter · Facebook Copyright © Byrds Research & Publishing, Ltd., 1997–2011. All rights reserved. |