Three or four years ago the price tag of 50-60 USD for a premium cooler would round the eyes of many users: "Man, that's expensive! I'll find a better use for my money!" But time passed, the market developed, user stereotypes changed owing to negative experience with budget products. The common trend of new consumer preferences was quite clear: noisy minimalist boxes gradually stopped being the typical solution; computers descended to the level of consumer electronics like DVD players with corresponding ergonomic requirements; even common users, distant from purely technical nuances of bought products, came to understand trivial logical installations, that fruitful symbiosis of functionality and quality cannot be obtained with low-cost solutions.

A wide range of High-End coolers today is not a shocking discovery to anyone. Moreover, they have blended with objective reality like traffic jams. By the way, the sector of premium coolers is ruled not by traditional brands now, but by second-tier manufacturers, who usually don't suffer much from excessive bureaucracy, which is the case with the former companies. They are not afraid to take risks, and they can design very interesting engineering ideas. One of such "new wave" players is Noctua, a young but quite authoritative brand, born in wedlock of Austrian distributor Rascom GmbH and Taiwanese cooler maker Kolink International. Young age is not a problem to this company: Noctua's product range includes a lot of promising models with interesting technical designs. This also concerns the NH-U12P headliner - a remarkable cooler for its class to be reviewed today.

First of all, let's examine technical properties and usability of our product under review and then analyze purely practical functionality of Noctua NH-U12P according to our updated test procedure.

Design

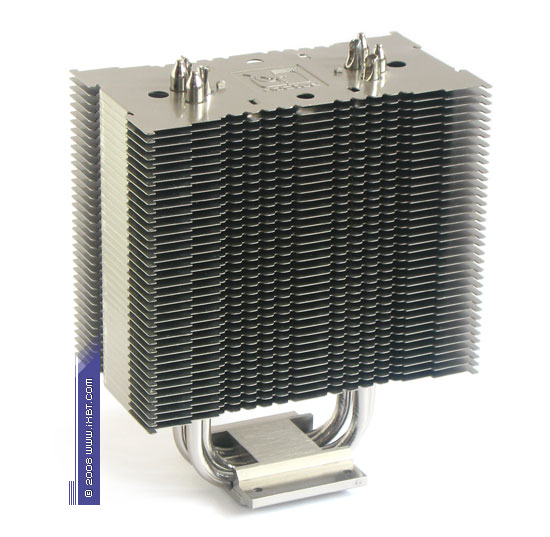

As a serious High-End product, the NH-U12P cooler effectively combines charismatic appearance with advanced technical design. Indeed, it's an impressive cooler - its working medium comprises a copper heat sink (45x42x5 mm), four copper heat pipes (6 mm in diameter), and a large aluminum fin-stack (effective dimensions - 126x72x105 mm) with the bundled fan (120x120x25 mm, 1300 rpm).

The NH-U12P can also boast of a good configuration: along with the advanced fin-stack (36 fins, 0.3 mm thick, the total heat exchange surface area is about 5500 cm2), the heat sink uses two thermal ameliorants - increased fin step (3 mm) and wave-like profile of the front edge.

That is the primary objective is "loud and clear" - the working medium of the NH-U12P is designed to reach optimal agreement with slow (and thus quiet) fans that generate low-pressure air flows: the wave-like edge eliminates some negative effects at the entry to interfin channels by turbulizing the air flow; and the increased fin step contributes to minimizing hydraulic resistance of the heat sink, and thus raises the real air speed and contributes to increasing the resulting heat exchange coefficients.

Another important issue - this cooler is notable for technically good contact between the heat pipes and the heat sink with fins. As we already noted many times, lots of coolers use simplified dry joints between heat pipes and fins: it's hardly possible to minimize thermal resistance in such joints. However, the NH-U12P has all its joints between pipes and fins neatly soldered to guarantee comfortable conditions for heat exchange. Thus, it raises overall efficiency of the entire thermal structure of the cooler.

This cooler features a number of technical ameliorants - two thin steel rods that brace the fin section (for higher mechanical strength of the heat sink and for neutralizing structural noises), several groups of special cutouts-rests in the fins (for higher resistance to vibrations and accompanying interfin ventilation), as well as neatly nickel-plated heat sink, pipes, and fins. It all shows truly parental care of the guys from Noctua for their product, their desire to perfect each important detail. It actually refines the technical image of the NH-U12P working medium and forces this cooler to use its skills to the full extent in practice.

Design of the bundled fan (NF-P12) is no less interesting, it's probably even unique. Its main feature is special triangular cutouts at the rear edges of fan blades (Vortex Control Notches as Noctua puts it). Although there is a share of marketing in this engineering solution, its acoustic rationalism is incontestable: notches on the rear edge of a blade optimize vortex formation (they are right in the middle of the vortex zone near the outer edge of the blade and fan fitting), partially neutralizing the so-called "impeller hum" and smoothing over negative effects of noise interaction between impeller blades and stator columns. The notches may also indirectly affect the throttling characteristic, especially in medium or high speed modes.

The NF-P12 fan also has good aerodynamic parameters: crescent blades (for noise reduction), wide chord - 22 mm at the hub and 38 mm at the outer edge (airflow reference), tightly placed blades - 1.47 solidity factor at the hub and 1 at the outer edge (static pressure reference), balanced "working field" - 0.36 radius ratio of the hub and blade (airflow reference), moderately aggressive angles of attack - 50° at the hub and 25° at the outer edge (multiplicative reference of the airflow and static pressure). And, of course, we should mention excellent electromechanics - the self-stabilising oil-pressure bearing (SSO-Bearing) and a special "smooth communication" circuit (SC-Drive) that suppresses electric structural noises (engine popping). Out of doubt, the NF-P12 fan is a worthy companion to the heat sink, together they form a harmonic duet.

So, we've covered individual features of the NH-U12P. We've got only the most favorable impressions so far. And now let's address its usability.

Write a comment below. No registration needed!