|

||

|

||

| ||

or an Extreme Processor Needs an Extreme CoolerNot long ago computer enthusiasts had a good grouse to complain about high heat release of top desktop processors from Intel. It passed the 100W mark and had no prospects of going down. The company even had to cancel the previously planned 4GHz Pentium 4 on 90nm Prescott core. Rough-and-ready Smithfield (800th series) processors with two Prescott cores, also manufactured by the 90nm process technology, couldn't pass the 3.2GHz mark, because raising their frequency even by one step resulted in big problems with heat. In fact, the 90nm process technology in combination with Intel NetBurst microarchitecture is the notorious stumbling block, the corporation bumped its head many times against it. In the beginning of 2006 Intel tried to improve the situation with Pentiums based on the latest 65nm process technology. The attempt was even partially successful, because 65nm Presler cores, even paired in a single package, easily mastered 4GHz (unofficially) with lower heat release, laboratories even obtained 5GHz. But the old sins still did their part. The corporation had to give up NetBurst for lost. However, 65nm Pentiums improved Intel's reputation even for the first six months, because they did fine with weaker cooling systems in most cases. You had to use advanced coolers only for top processor models or for overclocking. Intel had been preparing the revolution well in advance. In summer, 2006, the corporation launched several series of processors with the "absolutely new" Intel Core microarchitecture, which retained only crumbs from NetBurst (some crumbs!) Its basis was inherited (and improved) from Pentium III — Pentium M — Core Duo. The key advantage of this microarchitecture is significantly increased performance at significantly reduced power consumption. Let's dwell upon the latter.

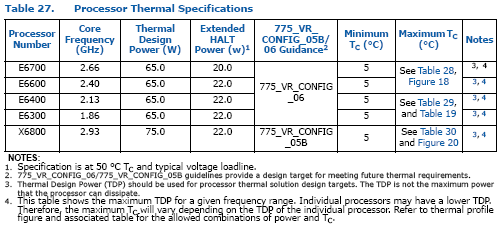

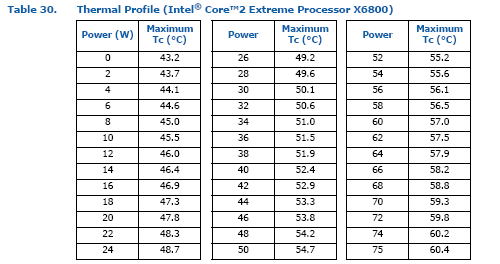

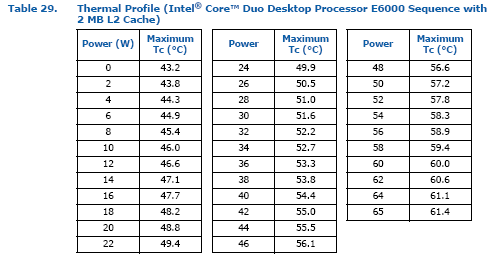

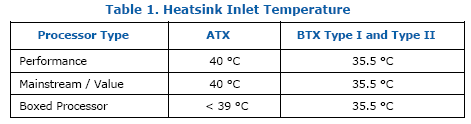

Core 2 – what about its temperature?As the corporation likes to stress out, the upgrade to Core 2 made the top desktop processors from Intel 40% faster and 40% more economic (that is, colder). Speaking in terms of official specifications, TDP (typical dissipated power in active mode) of modern dual-core processors Intel Core 2 Duo 1.86-2.67 GHz is just 65W versus over 100W in top Pentium D processors. If we take top extreme processors, Intel Core 2 Extreme X 6800 (2.93GHz and higher) "typically" dissipates 75W, while Pentium Extreme Edition 965, 955 and 840 offer 130W TDP (the real power consumption of these processors intensively loaded by special programs is higher by another several dozens of Watts).  However, after this article was written, Intel launched its first 4-core processor Core 2 Extreme QX6700 with 130W TDP (it's probably based on two 65W Core 2 Duo dice ;)), having caught up with itself in heat release in its old desktop processors. :) Hardcore sticklers for quiet and power consumption hadn't been happy for long. It may seem that Intel Core 2 Duo processors need 40% simpler, less powerful and less expensive cooling systems. But that's not quite true. The fact is, the reduced TDP comes at a cost: while the maximum permissible temperature in the center of Pentium's heatspreader (metal cap) was 68.6°C (or a tad higher, depending on a model of the processor), this threshold has ben lowered for Intel Core 2 family by almost 10°C to 60.1-61.4°C depending on a model!    Most reviewers of the new microarchitecture from Intel prefer to hush up this critical fact in their rhapsodies. That is, the new Intel processors require much lower operational temperatures, meaning a better cooling system! If we roughly estimate the required characteristics of coolers for Core 2, we'll find out that thermal resistance of coolers for Core 2 processors (ceiling temperature of 60°C) inside a PC case with the average temperature of 35°-40°C (taken from Intel specifications)  must be similar to that for Pentium D processors (ceiling temperature of 70°C.) That is the 40% advantage in power saving results in a 30%-40% loss in permissible operating temperatures (you can estimate it by yourself - divide the difference of maximum CPU temperature and air temperature by the TDP of a given processor). For example, the required thermal resistance of a cooler for Core 2 Duo (according to Intel guidelines) is (60°C-40°C)/65W=0.31°C per Watt! Far from any modern CPU cooler (you can read our review as an example) actually offers such outstanding characteristics (Intel sets a tad lower requirements to coolers for Core 2 processors inside BTX cases - 0.38-0.4 C/W). However, if we provide the intake of cold air into a PC case, reducing the temperature inside to 30°C, the requirements will be lowered to approximately (60°C-30°C)/65W=0.46 C/W. It's quite a wide-spread characteristic, though not that frequent among budget coolers. We can see that despite the significant reduction in power consumption of the latest desktop processors from Intel, requirements to their cooling systems are not eased down. Powerful evolving coolers for Pentium 4 and Pentium D come in handy now in order to avoid overheating of Core 2 processors above the critical 60°C mark. Moreover, the growing popularity of overclocking lower Core 2 Duo models (fortunately, they possess an excellent overclocking potential) with the connivance (inattention) to the above-mentioned problems with cooling these processors may result in a deluge of computer failures. By the way, thermal protection system (and throttling) in these processors is configured for the 81°C threshold, read our review. Theorizing aside, let's move on to the practical aspect — testing some latest (and some good models from the recent past) expensive coolers together with Intel Core 2 Extreme X6800, a top processor from the Intel desktop series at the time of this article. We'll try to find out how these coolers (designed for much more voracious dual-core Pentiums) cope with the new realia and provide permissible operating temperatures for new processors from Intel. But let's examine our coolers at first.

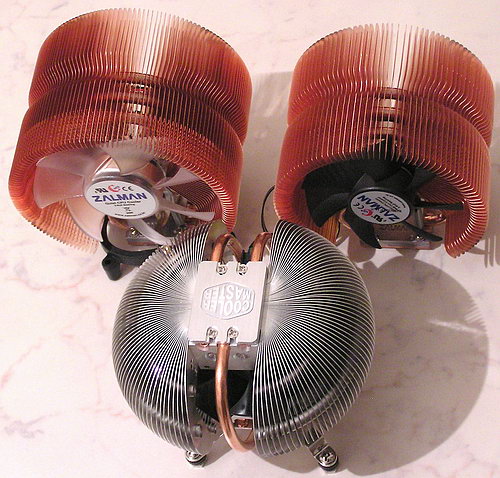

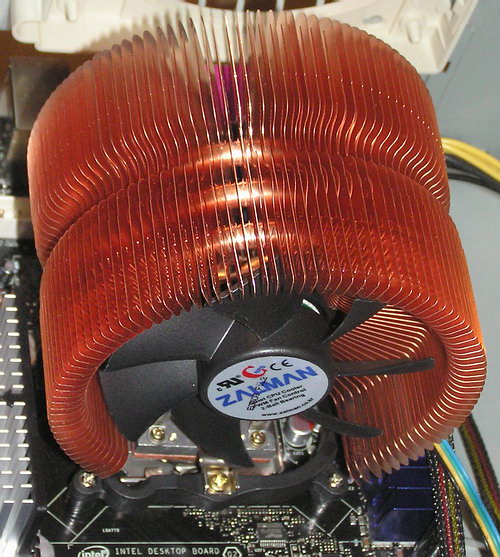

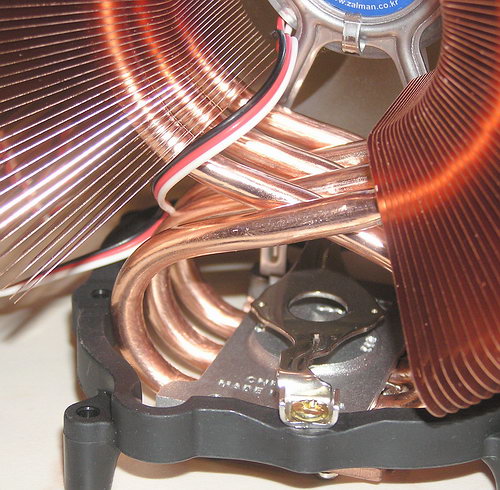

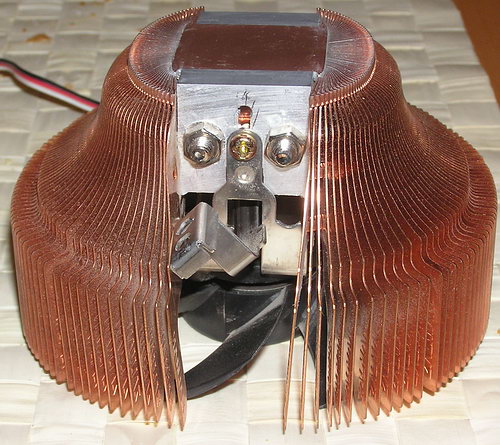

Zalman CNPS9500 ATThe first participant of today's "battle for degrees" against Intel Core 2 Extreme is the CNPS9500 AT cooler from Zalman — a famous manufacturer of hardcore solutions for cooling computer components.  This model appeared this year in spring. It's a cheaper modification (as far as possible for an elite solution) of the famous CNPS9500 LED — engineers sacrificed compatibility with AMD processors (AT can be installed only on LGA775) and used a fan without illumination. Besides, it's not bundled with FanMate2 speed control (of questionable value). In return the fan now has 4 pins for PWM control. In other respects it's the same all-copper triumphant CNPS9500 with fan-like fins (dissipation surface: 3700 square cm), three heat pipes (6mm in diameter) that go through the fins from both sides, and air flow parallel to the motherboard, though part of the airflow goes to the board near a processor.  The 92mm fan of the CNPS9500 AT is marked ZM7-PWM. It's equipped with two ball bearings (rather quiet) and consumes no more than 230mA from the 12V line. Maximal rotational speed is about 2800rpm, minimal speed (powered from the 5V line) is about 700rpm, but PWM control may yield even lower results. It's fantastically quiet in this mode (our tests prove it), but it maintains its high thermal efficiency. This cooler would have been a top solution from Zalman in this review, but for the latest Zalman CNPS9700 LED. It's a huge model with great features, which was not even available on Zalman's web site when we wrote this article. :)

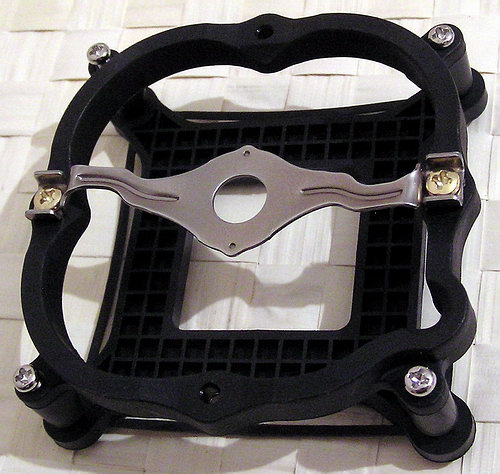

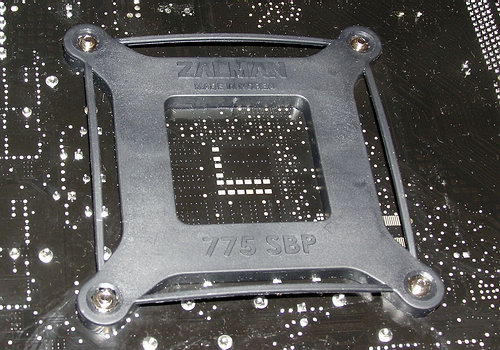

Zalman CNPS9700 LEDThe CNPS9700 LED carries on the glorious tradition of the CNPS9500 series, copying all its successful design gems.   But on a greater scale — in fact, the 9700 is just the enlarged 9500 LED (approximately by 20%). :)  Diameter of the 9700 fan has grown from 11cm to 13cm. The device is a centimeter longer, two centimeters higher, and the heat pipes are now a tad thicker. A section of 0.2mm copper plates forms a well-ventilated fan with the large heat exchange surface (5490 square cm, 1.5 times as large as in the 9500 models). Almost the entire surface is effective — both in the center ("rings" of thermal contact with the heat pipes) and at the outer radius.  We should again mention the excellent quality of the contact between the heat pipes, fins, and the heat sink, which minimizes thermal resistance of their contact. And the cast copper base is polished almost like a mirror.  Besides, now it uses a 120mm (instead of 90mm) transparent fan ZM97L with two ball bearings, maximum current drain of 400 mA and blue backlight.  Its rotational speed is also about 2800rpm from the 12V line and drops to 1300rpm from +5V. The CNPS9700 LED is equipped with a 3-pin fan (no PWM features) that comes with FanMate2 (manual rpm control).  It's a multi-socket cooler, but it may be followed by the LGA775 modification with a PWM fan. The cooler is mounted on the motherboard just like the 9500 models (the retention modules are actually interchangeable): a special metal bracket that presses the center of the cooler base  either to two holes on the motherboard with an AMD processor or to a plastic frame for LGA775, which is secured on the back side of the board to a counter frame with four screws.

The cooler is pressed tight to a processor, but the PCB is not distorted much. The cooler can be installed in any of the four possible orientations (there is a recess in the upper frame for the LGA775 lever),  but the most optimal orientation is when the air is taken from the front of the PC case and is driven out of the cooler right into vent holes on the rear panel. In this case you can actually remove a rear panel fan, which drives the hot air from a PC case, because the 12cm fan in the CNPS9700 LED cooler does this job.  The cooler is shipped in a nice semitransparent box.  Zalman CNPS9700 LED is bundled with a retention module, FanMate2, as well as a detailed installation guide  and a new thermal compound — Super Thermal Grease ZM-STG1 used in all our tests.  It differs from the typical Zalman thermal compound in a white tube not only in color (dark grey instead of white), but also in thickness — it's much more fluid than usual (that's why it is shipped in a glass vial with a brush, like nail polish). It contributes to better contact between the cooler base and the CPU (narrower gap and fewer micro bubbles). Unfortunately, the manufacturer does not publish the composition of this paste (judging by the color, it may contain micro power of aluminum nitride), but its main characteristics are published on the official web site. According to Zalman, ZM-STG1 reduces CPU temperature by another several degrees. * * *

Besides, our list of contenders includes three more coolers: 1. GlacialTech Igloo 5700 MC based on heat pipes. It's an all-aluminum heatsink with a massive base and a high-speed fan. It demonstrated very good (ones of the best) heat emission results in our previous reviews, partially due to very tight contact with a processor.  2. "The old lion" — famous copper cooler Zalman CNPS7000-Cu, which gave rise to an entire series of copper coolers from this company (it was an ancestor of the 9500 model and some others). Its fan is similar to the one installed in the CNPS9500 AT. I raised the retention bracket a little, in order to fix this cooler well on the plastic frame from the CNPS9500 on LGA775 Socket. That is this old model can be also used for LGA775 (only minor modifications are required).  These two coolers will also be used as good reference points for comparison of new products with other solutions, tested in other testbeds. 3. The new original cooler Mars from Cooler Master, we'll review it in detail in the next article of this series.

Table 1. Coolers' Specifications.

Unfortunately, Zalman specifications obstinately do not include such parameters as fan service life, its performance, and air pressure. Even thermal resistance can be read only in several specs, though this is hardly the property the company should be ashamed of. ;)

Procedure for Evaluating Heat TransferAnd now let's proceed to the competition of these hardcore coolers for lower temperatures (remember, we need to get 60°C or less ;)) of the top desktop processor from Intel - Intel Core 2 Extreme X6800. To make the task harder, we'll overclock our processor by one step — let it operate at 3.20 GHz (standard FSB frequency - 1067 MHz, see the screenshot),  dissipating about 82W for typical operations (75W*3.2GHz/2.93GHz). Thus, it will represent a hypothetical CPU to follow the X6800 (out of doubt, Intel will launch this product). Grapevine has it that heat dissipation of the future top Intel processors from this series will be a tad higher than in the present models (especially future 4-core processors). Besides, 3.2 GHz is a guaranteed level, to which Conroe processors can be overclocked without any problems. So we also evaluate "capacity" of these coolers for overclocking Core 2 processors. Heat release tests were carried out with the Intel D975XBX motherboard on Intel 975X Express chipset, Intel Core 2 Extreme X6800 processor on the 65nm Conroe core (1067 MHz FSB, 4MB Cache), 1GB DDR2-533 memory, and ASUS AX800XT video card (ATI X800 XT). The motherboard was installed in a (closed!) standard middle-ATX case Palo Alto PA-810 with the HiPro HP-W460GC31 PSU (460W), the quiet and "cold" WD800JD HDD, and one 90mm on the front panel to drive the air into the PC case at 2500rpm. Coolers were arranged to drive the air towards vent holes on the rear panel (we removed the fan there). Room temperature during our tests was kept at 22°C. Temperatures of the processor and motherboard (near the CPU voltage regulator) were read by built-in thermal sensors and Everest Ultimate Edition 3.01.652, SpeedFan 4.30 and Intel DCC under MS Windows XP SP2. We also registered the rotational speed of the CPU cooler. CPU was loaded by the Conroe-optimized S&M 1.8.1 on three different levels:

Of course, we also took readings of the idle system (0% load). EIST technology was enabled during our tests, because it corresponds to real situations. That's why the processor dropped its clock rate to 1.6 GHz when its was idle. This situation is illustrated by RMClockv 2.15. It was used to make sure there was no throttling in the course of our tests (we disabled the standard tools of activating throttling for the time of our tests). All coolers were tested in two operating modes: powered from +12V (see the top part of the diagrams) and from +5V to reduce the rotational speed (we used standard tools of the coolers and the speed controller bundled with GlacialTech Igloo 5700 MC), see the bottom part of the diagrams.

Results of Heat Release TestsLet's start with the hottest case under maximum (100%) CPU load in S&M 1.8.1. This load is usually generated by intensive computations in FPU processor units and rarely occurs in real life for a long time. Nevertheless, most contenders cope well with cooling the processor to 60°C and lower even in such extreme conditions. The huge Zalman CNPS9700 LED can do it even at reduced rotational speed, powered from +5V. But on the whole, it's not recommended to use reduced rotational speed for such high loads on Core 2 Extreme even for expensive and advanced air coolers. Only the War God from Cooler Master disappointed us a little. Its design and materials do not allow it to fight well the slightly overclocked Core 2 Extreme. But the old Zalman CNPS7000-Cu is a joy. It cooled the PCB around the socket to the lowest temperature. However, if we switch to a more realistic CPU load (75% S&M), our contenders cope well even with the overclocked Core 2 Extreme. If the processor is not overclocked at all, our coolers cope with the task even at a significantly reduced speed (except for Mars). That is it's quite possible to cool an extreme processor quietly, but it comes at a cost. But if this processor is used in an unusual way — plain office or multimedia work generating 50% load (S&M), it simplifies the situation. Almost any contender can reduce its speed at least twofold even for a slightly overclocked processor. When idle, Core 2 temperature goes below 40°C almost in any case — thanks to EIST. Interestingly, the old Zalman CNPS7000-Cu is again the best at cooling the motherboard under the processor. Cooler Master Mars falls short of the occasion.

Acoustic testsWe measured the noise generated by coolers using the VSV-003-M3 sound level meter according to our test procedure. We measured the level of sound pressure at a distance equivalent to one meter (according to our State Standard), weighted by the A spectral curve. According to this device, the background level of a quiet room is 20.5 dBA. We measured the sound level (pressure) in a diffuse field at 25cm from a fan. The results were recalculated to the 1m distance by subtracting 12 dB. These results are almost no different from the specification values at the lowest noise levels (the most critical to measurement error). Maximum noise results of some coolers match our previous noise readings of the same coolers made by the other test procedure. So we can draw a conclusion that our approach to measuring cooler noise is correct and provides real numbers. Our noise readings are published on the diagram together with fan's tachometer readings. Just as we expected, the quietest cooler is Zalman CNPS9500 AT operating at 660rpm. Unfortunately, in this noiseless mode it can cope only with the office load of the processor. Our favorite is Zalman CNPS9700 LED. Even at significantly reduced, hardly audible rotational speed (1300) of its 120mm fan, it demonstrates a decent cooling level of the actively working extreme processor. Out of five contenders, the noisiest outsiders are Cooler Master Mars and GlacialTech Igloo 5700 MC. While a high rotational speed of the latter allows the cooler to cope well with the Core 2 Extreme even in overclocked mode under heavy load, Mars does not perform very well.

ConclusionSo, despite the significantly reduced power consumption of the latest desktop processors from Intel, their requirements to cooling systems are not eased down. It has to do with the fact that the maximum permissible cap temperature of these processors has come down to 60°C versus 70°C for Pentiums. Thus, powerful coolers, designed for Pentium 4 and Pentium D, will come in handy now to keep Core 2 processors from overheating above the critical 60°C. We'll have to forget about simplifying coolers for Core 2 for now. According to our tests, the latest and some old top coolers cope well with cooling even slightly overclocked extreme processors on Conroe core to 60°C. That is the reserve of thermal efficiency of such coolers can be used to reduce their noise to a nearly inaudible level. The modern leader here is the latest Zalman CNPS9700 LED, which inherited the best features of its famous predecessor CNPS9500 LED/AT (this cooler still performs well). Zalman CNPS9700 LED gets our Original Design award for its thermal efficiency.  At the same time, not all advanced (extreme and expensive) coolers can efficiently cool Core 2 Extreme. Here is an example of a poor, but original solution - the Mars cooler from Cooler Master, which is outperformed by the cheaper and simpler GlacialTech Igloo 5700 MC as well as by the old Zalman CNPS7000-Cu. Aluminum is evidently outperformed by copper in extreme cooling systems for modern desktop processors. You shouldn't even read this article to make sure it's true. ;) But... This eternal contest is not so straightforward. Expect surprises in the next article of this series.

Write a comment below. No registration needed!

|

Platform · Video · Multimedia · Mobile · Other || About us & Privacy policy · Twitter · Facebook Copyright © Byrds Research & Publishing, Ltd., 1997–2011. All rights reserved. | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||