|

||

|

||

| ||

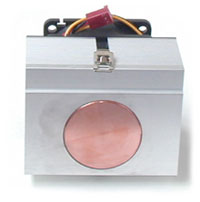

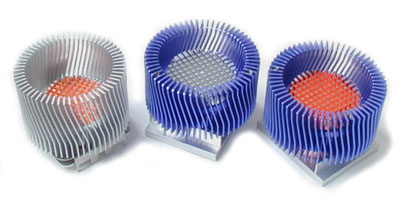

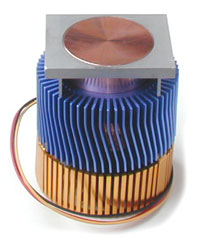

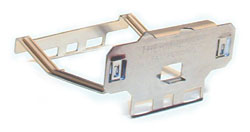

The last half a year turned out to be quite successful for Thermaltake: almost twenty new products were released under the Thermaltake's trade mark, sales in the USA and Europe became much larger, its popularity grew also in the overclocking world. Moreover, the company Thermaltake wasn't aside after the tragedy in the USA having granted a lot of coolers of $10,000 to one of Online-shop for the following transfer of the proceeds to the Red Cross. So, today we are going to take a look at 3 new coolers from the Volcano series and several new ones from the Dragon Orb. First impressionsLet me start with the Volcano series - Volcano 5, Volcano 6Cu and Volcano 6Cu+.  The Volcano 5 is a follower of the Volcano II and differs from the latter in a larger heatsink (80X60X40 mm against 60X60X40 mm) and a complicated profile (20 internal fins against 18). But exactly these differences make the heat-transfer surface almost twice larger. And I must say that the new model is really more efficient than the old one.  There is one more detail which the engineers has changed: it is a corrugated surface of outer fins. Though I don't think it will have a huge effect on the productivity.  The Volcano 6Cu is very similar to the Volcano 5 but for a copper disc of 40 mm in diameter located in the central part of the base. Copper has a much larger coefficient of heat conductivity and a bit larger thermal diffusivity. Therefore, it is better to use copper where the processor touch the heatsink in order to decrease thermal resistance. But of course, there are some drawbacks: heat loss in the place of coupling of the disc and the base. Although it is impossible to avoid them, the modern technologies are able to reduce these losses. And they are reduced, though not to the most possible extent. Another shortcoming is traces of a cutter on the copper disc. But in the Volcano 6Cu/6Cu+ coolers (as well as in the Dragon Orb) it is easy to eliminate it as the configuration of the base is much "friendly" to polishing than that of their predecessors. As to the Volcano 6Cu+, the plus in its name means a more rapid cooler (6800 RPM). In all other respects this model is identical to the Volcano 6Cu, that is why we will omit it and take a look at the Dragon Orb coolers.  Their appearance is really striking. The engineers have gone an extra mile in eliminating errors of the Golden Orb series, and now the Dragons look much more attractive. The fan is at last taken outside a 60-fin contour to increase efficiency of ventilation. Moreover, in the Dragon Orb 1 and Dragon Orb 3 the inner cylinder has twice higher fins than in the Mini Copper Orb. It means that the efficiency is again better.  The inner cylinder is now twice higher, and it causes some problems. If a surface of a heat source (here it is a processor core) is considerably smaller than a surface of a contacting material (the inner cylinder), an effect of spreading resistance takes place, which increases a thermal resistance of the material. We can fight this effect by making the cylinder higher (to the definite extent). But if it does the Dragon Orb 1 good, in the Dragon Orb 3 the copper cylinder makes the cooler weighing 750 g!  Another change in the coolers is that its base in now 6 mm think instead of a 1mm plate like in the Chrome Orb, Super Orb and Mini Copper Orb coolers. Probability of flexure is now almost zero, and the Dragon Orb coolers can be easily installed into a socket without being distorted. Now a little on the Dragon Orb 2.  The Dragon Orb 2 has a completely different configuration of the inner cylinder, namely its end. There is a plate of a different aluminum alloy with 30 copper fins of a trapezoid form which are 24 mm high and 0.5 mm wide. Although the idea is original, the Dragon Orb 2 hardly outscores the Dragon Orb 1. As a result, this relatively expensive cooler is not profitable... InstallationThe first question I think you'd like to ask me is whether there are any problems in installation of the new Volcano coolers because of their dimensions. Well, at least in the Socket A motherboards the keepout area provides for installation of coolers with the heatsink base up to 80X60 mm. In the Socket 370 boards the keepout area is a bit less, that is why you'd better to make all necessary measurements before choosing a cooler. The fastening clip in the new Volcano coolers is identical to that of the Volcano II. Besides, installation of old Orbes was prevented by capacitors surrounding the socket. Now this problem is solved. Apart from thermalphysic advantages of the new Orbes the higher inner cylinder of the Dragon Orb gives technical ones: despite the fact that the external 60-fin contour still measures 69 mm, its lower edge is located 16 mm above the base. Taking into consideration that the external contour towers over a motherboard by 26–27 mm and that capacitors are usually not higher than 20–22 mm, we have at least 4 mm in reserve.  Another advantage of the Dragon Orb is that it is much simpler to mount now. First of all, there is no anymore a clip tightly fastened on the heatsink. Secondly, it is more convenient as you can use a screw-driver of almost any size or even install/deinstall it manually. And at last, all 6 fastening cogs of the Socket A are used, which makes almost impossible that a cooler warps. But you should take careful fastening of the clip in the socket otherwise it can cause serious troubles. The specification of the new thermo interface (Bergquist Hi-Flow 225-U) are worse than that of the Thermagon T905C (a transfer into liquid phase is at 55 °C, heat conductivity is 1 W/mK). However, it turned out that the temperature in case of the Hi-Flow 225-U is 2–3 °C lower than with the Thermagon T905C. Nevertheless, if we compare the Hi-Flow 225-U and good thermo grease, for example, AlSic-3, the thermo interface yields to the latter 5–6 °C. TestsLet's start with the stress tests. The Everflow F126025DH fans (in the Volcano 5 and Volcano 6Cu) and Everflow T126025DH ones (in the Dragon Orb A1134, A1133, A1132) working at the rated speed of 4900 RPM passed all tests flawlessly. Despite some heat-up these fans worked stably at the increased power supply (17 V) and when the impeller stopped for a long time. At the decreased voltage (7 V) they ran stably as well without any vibration. Unfortunately, the Everflow T126025BUA fans (in the Volcano 6Cu+) and F126025BUA (in the Dragon Orb A1137, A1136 and A1135) operating at 7000 RPM didn't pass our stress tests. While at the increased and decreased power the fans worked quite good, they failed to keep running when the impeller stopped for a long time (after 5-7 minutes). The mechanical part is excellent: quality of the bearings is high, the shaft-bearing gap meets the technical requirements, and the grease is also of high quality. Now come the temperature tests. The test equipment remains the same:

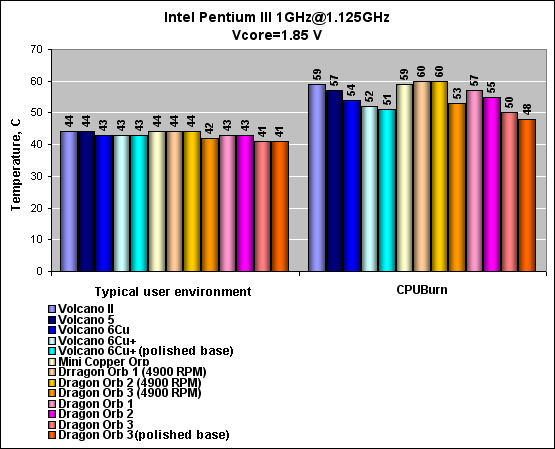

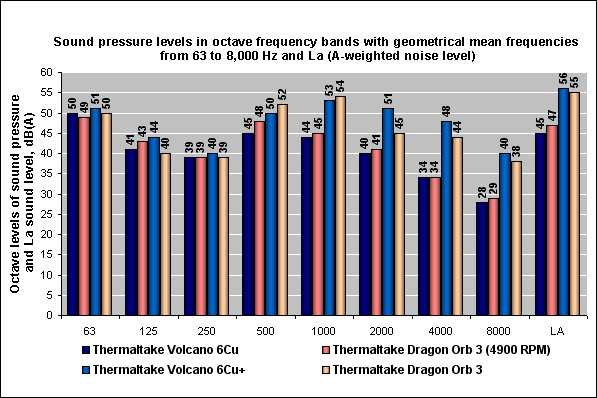

We used the CPUBurn utilities for warming up the processor and the MBProbe 1.30 one for temperature control. Temperature measurement results Notes: The AlSil-3 grease was used as a thermo interface. The diagram shows the overall result And now are the noise measurements.  Note: The background noise level is 26 dBa Since the noise spectra of the Dragon Orb 1 and Dragon Orb 3 were identical and differed from that of the Dragon Orb 2 only in two octaves (500 and 2000 Hz) by 0.5 dB, the diagram shows only the spectrum of the Dragon Orb 3. The Volcano 5 and Volcano 6Cu also have equal noise spectra. Therefore, the diagram shows only the Volcano 6Cu. ConclusionIn the last summer Thermaltake did it best: they released 9 new models of coolers for Socket A / Socket 370 processors. And the coolers turned out to be rather good! Of course, you should account for such drawbacks as a too high noise level and a small reserve of the electric strength of the 7000 RPM fans. But these downsides are outbalanced by the advantages:

All these coolers are freely available at quite

an attractive price!

Write a comment below. No registration needed!

|

Platform · Video · Multimedia · Mobile · Other || About us & Privacy policy · Twitter · Facebook Copyright © Byrds Research & Publishing, Ltd., 1997–2011. All rights reserved. |