The plant where Siemens produces DECT phones is

located in Bocholt (Germany), an hour of driving from Dusseldorf.

It is the only plant of the company that manufactures DECT devices,

and one of a few in Europe. The town the factory is situated in

is not large, there are only 40,000 inhabitants. The plant employs

3,585 people, where 2,734 are workers and others are administrators,

developers and engineers. The plant was founded in 1941 and worked

for the German army. In the end of the war the factory was severely

damaged and was recovered only in 1946. By 1948 the production of

wired phones was set going, mainly thanks to the help of local people.

In general, they were specialists which had been working at the

plant from the very beginning. The factory worked without any changes

up to 1997 when a new production shop, 10,000 sq. m., was built.

The new facilities appeared due to a growing popularity of the DECT

standard and DECT wireless phones. Let me dwell on the history of

development of Siemens' DECT phones.

In 1991 the plant was still producing analog devices

of the Megaset series (Models 900 and 910). Two years later a new

series, Gigaset, was added to its arsenal, and the first model -

Gigaset 1000 was released. As the product turned out to be successful,

next year the company launched its modification - Comfort which

possessed several new technical characteristics. At that time there

were primarily two basic types - Classic and Comfort, which didn't

differ much from each other (the differences related only to the

convenience in use). In 1998 Siemens developed a new model - Gigaset

Pocket, the first DECT phone of small dimensions (110 cu. cm.) comparable

to contemporary cell phones in this parameter. The Micro line extended

this direction. In 2000 the DECT standard began supporting a lot

of other products apart from phones. The brightest example is a

home automatic telephone exchange supporting up to 10 receivers

and 2 ISDN lines. Today there are many devices using the DECT technology,

for example, Siemens Simpad SL4 web-pad. The DECT line now includes

Siemens 4010, 4015 of the Classic, Comfort and Micro series.

The first thing that catches your eye is a great

deal of ads of cell phones manufacturers. On the photo you can see

a huge advertisement hoarding mounted against the entrance. A great

variety of smaller posters are spread all over the territory of

the plant.

In the checkpoint hall there are several stands

with different phone models and a screen which plays ads of new

handsets. In the office building you can see a phone made of unbroken

wood.

Having put on overalls we take a few steps and

get into a production shop. It is rather quiet here, the floor is

covered with antistatic coating since components of phones and assembled

devices are sensitive to statics.

The first line produces phone cases. In fact, all

lines can manufacture any current model. On the photos below you

can see how presses form blanks which are afterwards driven to the

production line by conveyers. The front panels are manufactured

in two stages as they have dirrerent trims; they are also pressed

but at the second stage.

After that cases are checked to meet the quality

requirements and then delivered to the next pipeline to get labeled.

You can draw any mark you like, but it will be

profitable only if there are not less than 50,000 phones. The largest

part of investments is required not for changing a logo but for

changing information in all Siemens' catalogs.

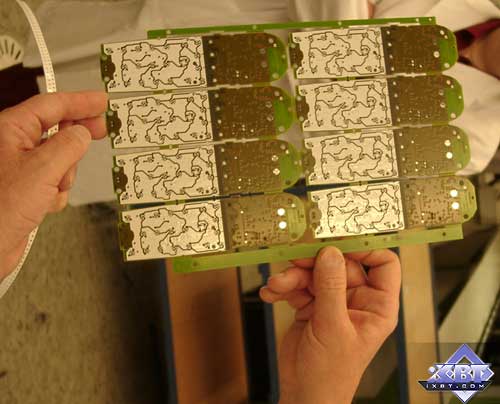

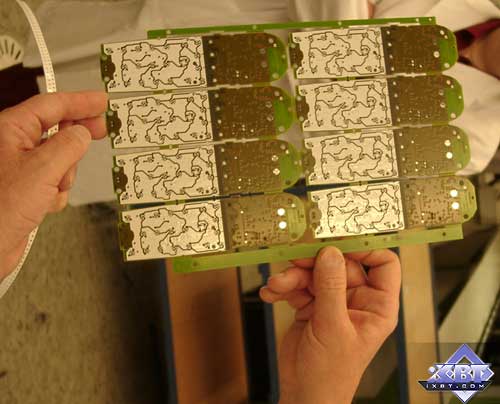

Another line deals with processing of printed-circuit

boards for future phones. One plate houses 8 blanks. The boards

have 6 layers, at the first stage they are covered with conductor

lines and then with solder to fix components.

In front of the production lines you can see an

amusing poster with a an appeal to increase labor productivity.

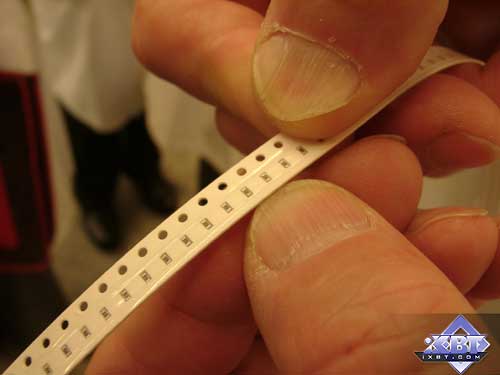

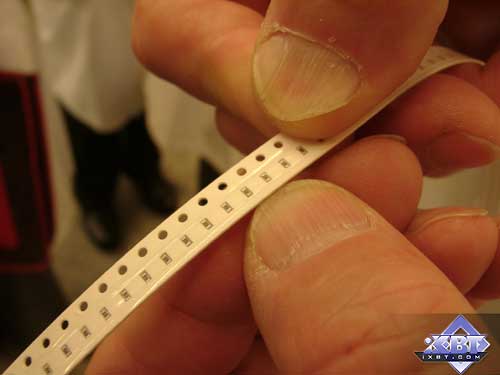

After that small components are set onto the boards;

they are put into tapes wound round reels. First these minor details

are not soldered to; on the photo you can see how small they are.

Then it is a turn of larger components and only after that all of

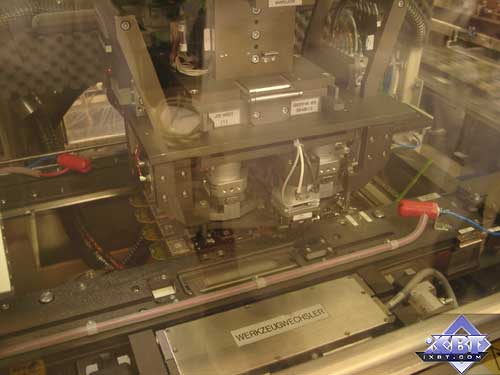

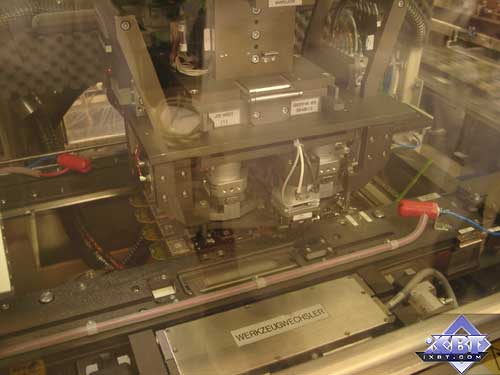

them are soldered to the board. By the way, the machines installing

the components on the boards are developed by Siemens and are said

to be quite popular with various firms and companies all around

the world.

In a special chamber the solder melts and gradually

fixes components. The temperature increases in 8 steps, then drops

in 2 steps and then the plate is sawn into 8 boards. The quality

control is carried out at each stage. The lines are almost completely

automated, and in case of any problem they either produce a signal

or stops working until an operator solves the problem. Above the

most of the lines there are three-color lamps looking like traffic

lights. If everything is OK, the green is on, in case of an uncritical

fail (for example, components are over) the yellow gets on, and

the red will inform you about serious troubles. The side effect

of automation is reduction of the stuff.

The finished boards are packed in trays. Of course,

all of them are tested, and defected samples are weeded out. On

the next line the boards are set into cases: first come small details,

for example, speakers, then key-pads and after that - the boards.

Finished phones proceed to inspectors who pack them into soft paper.

Then comes the final packing and the phones go the the stock. The

workers covering phones in paper examine for any scratches or abrasions.

Then we saw how packages of the phones were stored,

and how chargers were put into the boxes.

Boxes with chargers proceed to a small line where

workers put wrapped phones into them. After that the sets are driven

by the conveyor to the last selective check-up and then go to the

stock. If a worker forgets to put some accessory such box returns

as there are electronic scales which collate weights of the boxes

with the standard one.

Here is a cart with new phones.

You see, the production process is very simple

and highly automated. The corporate culture is of the greatest importance

here which means the through control from the very beginning up

to the end. Phones produced in Europe and Asia often differ in quality.

While the technologies are the same, it is the corporate culture

which is often lacking. It is well known that European product is

almost three times dearer than a similar one somewhere in Asia.

The Siemens' representatives say that the Bocholt's plant won't

be moved anywhere in the near future. During the last year the factory

produced about 12 million DECT phones. The lines work 24 hours a

day, 6 days a week or sometimes 7 days. This is another evidence

of wide popularity of these devices.

Write a comment below. No registration needed!