|

||

|

||

| ||

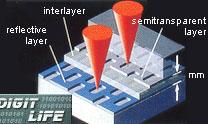

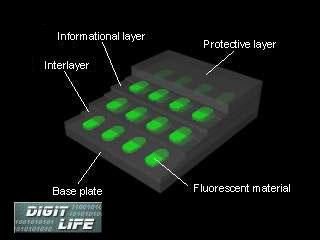

Compact discs were a revolutionary product at its time and influenced many spheres of human activity. People started recording music of high quality which didn't get worse with the time as it happens to be on tape or vinyl. As soon as CDs appeared in computer industry they immediately became an undoubted helper both for users and for programmers. The latter were able to increase volume of their program products by adding video and audio elements etc. Later discs were used for digital video (VideoCD). But technologies are progressing. Data are growing faster and faster. A usual CD is far not enough (640 MBytes). So, there appeared DVD technology. Of course we are happy with those 17 GBytes that can be kept on one DVD disc, but this is a limiting point. So we need a completely new method of storing information on portable data medium. And at last, the company Constellation 3D demonstrates a new format: FMD (Fluorescent Multilayer Disk) which can soon become a leader. Constellation 3D Inc.(C3D) The President and Executive Director of the company C3D is a physicist Evgeny Levich. The company C3D was founded in 1995. The company is aimed at developing progressive technologies in the field of data storage and in production in the sphere of consumption and education. Constellation 3D provides revolutionary solutions in the sphere of data storage and it positions itself that all their announced products must set the pitching high-efficiency technologies of data keeping. The company has opened their offices in New-York, Florida and California, and some laboratories in Israel and Russia. The company possesses over 60 patents. The first generation of disc productions from Constellation 3D will be a family of 120 mm multi-layer FM-discs with capacity up to 140 GBytes and with read speed up to 1 GBytes/s. It's interesting to compare them with DVD that keep up to 17.4 GBytes. New discs will be capable for example to keep up to 20 hours of compressed movies in HDTV format. FMD-ROM: operating principleOn the picture you can see how a FMD-ROM looks like.  You can see that a disc is transparent. But where is a reflective layer like on CD and DVD discs? The matter is that this technology doesn't need it. Let's consider FM disc in detail. In optical discs such as CD, DVD and MĪ the process of reading is implemented the following way. A beam of a semi-conducting laser gets on the surface of an informational layer and then reflects from aluminum (or any other metallic) layer and fixed with a detector-receiver. In FMD there is no reflected laser beam: when a laser beam reaches an informational layer the latter starts radiating. The principle of operation of FM-discs is based on a phenomenon of photochromism. Some years ago russian chemists discovered a stable organic material a "stable photochrome" which when acted upon by a laser beam obtains fluorescent properties. The matter is that an informational element of FM-disc (photochrome) can change its physical properties (such as color and presence of fluorescence) under influence of a laser of a definite power and wavelength. Initially photochrome doesn't possess fluorescent properties. When switching on a laser a photochemical reaction starts what causes fluorescent properties to appear. When reading, this matter becomes excited again but with a laser of lower power. The fluorescence is caught up by a photo-receiver and is fixed as a value "1". Besides, according to the company there will be no worsening of the photochrome state with the time.  Excited photochrome radiates shifting the spectrum of falling light to the red color side within 30-50 nm what allows to differ laser signal from the light from the disc. Note that this technology allows preventing a problem of multiple inference between layers since the reflected light is not coherent; it passes through layers without any difficulties and is easily defined by a receiver. Let's talk about it a bit in depth. In usual optical discs (CD/DVD) with increasing number of informational layers a signal gets worse. It's explained by the fact that these technologies use a reflected signal, it means that there is necessity in mirror surfaces. That's why in DVD technology an external layer is made to be semitransparent in order to allow a laser to reach an internal one.  And a signal while passing an external layer leaves a part of its energy because of reflecting. Signals reflected from both layers interfere because of their coherence, it results in losses of useful signal. Increasing number of layers aggravates an effect of multiple interference between the layers what makes reading more complicated. The problem can be solved by improving detector-receivers, but it is possible only in laboratory. In case of fluorescent discs the quality of the signal gets worse much slower with increasing number of layers. Look at the graph below:  According to FMD-ROM developers, even with a hundred layers a useful signal will be acceptable.  FM-disc As you can see in the picture a disc consists of several plastic (polycarbone) layers connected to each other. A layer contains surface structures (pits) which are filled with fluorescent material. When reading a laser focuses on a certain layer and excites its fluorescent elements, and then this radiation is caught by a photodetector.  The developers state that with a blue laser (480 nm) it's possible to increase record density up to tens Tbyte on one FM disc. Another interesting feature is parallel reading. If we record a sequence of bits not along a track but deep into layers we can increase speed of data access. That's why such disc is called "3-dimensional". Here is a list of advantages of FMD/C:

Here is a table demonstrating one of the future projects of C3D: 50 GBytes disc (12-layer):

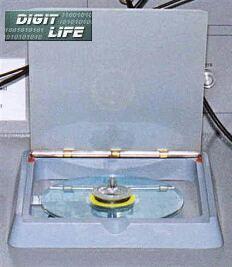

FM disc productionMany stages of their production are put on the basis of CD and DVD manufacture. However, some alterations are to be made here. In particular, they concern form of surface structures and methods of filling with fluorescent material. Besides, there is no technology of sputtering of aluminum layer what reduces the number of steps. Mastering process is very similar to that of CD/DVD. A few words on a process of manufacturing CD discs. As a storage device they use a glass plate covered with a thin photoresistive layer. A laser beam, intensity of which is modulated with digital information, gets into photoresist causing markings that correspond to bits of digital code. After that the photoresist is developed and covered with a metallic layer. This Master-copy after recording contains digital information in the form of pits. Then they make an exact negative copy by a galvanic way which later serves as a press-matrix. This negative can already be used for CD manufacture. But in order to save this single matrix they produce several intermediate copies (negative), and then several press-matrix (the same way) which serve for stamping CDs. After recording of data on an informational surface in vacuum a thin layer of aluminum is sputtered. Outside, the metallic layer is lacquered in order to prevent mechanical damage. In FMD technology an exact copy of pit is of vital importance since later it's filled with fluorescent material. That's why these two technologies differ. Here, a master-copy is a nickel matrix (a stamp). It is a negative copy, like in CD-technology. A FM disc consists of several layers that's why the process contains several steps: informational layers are produced separately and then they are combined together. Technological process of FM discs is divided into two types. In the first one there used a method of hot stamping. Each layer is reached by pressing of polycorbone layer with two stamps (Master-copies) at high temperature. So we receive one layer with two informational sides. Then, pits starts being filled with fluorescent material. And when it becomes hard the informational layers are pressed. In the picture you can see a structure of a 7-layer disc produced according to the described method.  The second method uses a process of photopolymerization when a multiple disc is reached by stacking of discs one after another which are made from thin informational layers. Manufacture of one informational layer lies in manufacture of plastic film with definite optical characteristics. The film is 25 to 30 micron in width. The film which will get information soon is either stamped or cut out with a laser. After that the film is installed on an external surface of a nickel matrix that carries a negative copy of produced informational layer. While rotating, photopolymer matter is evenly brought in in the space between stamp surface and plastic film. Later, when the photopolymer matter becomes hard the film get detached from the stamp surface. The base plate now contains pits of definite geometry. A pit's geometry is better in terms of quality than that received when manufacturing matrices for CD or DVD since those technologies use a process of stamping of pits. When a layer with the required position of pits is ready, they are filled with fluorescent material (it covers evenly the whole informational side). After that the surface is processed chemically in order to reach necessary contrast of pits and flats. Then, in order to check the copy for different defects, photoelements get excited and the whole picture is analyzed with the help of CCD cameras. After that the layers are "stuck" to the base plate 0.6 mm in width. And all this is covered with a protective layer which can be used for graphics decoration. In order to prevent a physical contact with informational layers on the edge of the disc this area is filled as well with polymeric material, like in CD or DVD technologies. FM read devices On the photo you can see a prototype of such device. The developers say that the drives intended for FM discs will easily understand CD and DVD formats. In structure the drives are similar to CD/DVD ones for example in such parameters as laser, optics, servodrive, tracking and focusing system, different controllers. There appear only systems that can catch and discern fluorescence, and a service in choosing an informational layer. Recording on FMD-ROMWe still haven't seen a prototype of record device but the company says that it is under developing now. There used a technology WORM (Write Once Read Many). A series of rewritable discs will be called FMD WORM. A technology of manufacturing these discs will be the same as for FMD ROM except the fact that they will use another fluorescent material which will be able to change the state under the influence of a laser. And when recording you should follow two rules:

Besides, it's very important to choose a recording method. The FMD developers offer two record principles. The first principle (thermal) implies usage of material which possesses fluorescent properties from the beginning (logical one). And when recording those segments which are thermally acted upon with a laser lose these properties (logical zero). The second principle (chemical) means usage of a material that doesn't possess fluorescent properties form the beginning. When acting upon with a laser a photochemical reaction starts, and the material gets fluorescent properties. There, a low-power laser is enough, or even a usual LED. With the latter (LED matrix) there is possible a simultaneous record of the whole array of information. Record devices don't differ much from read ones. The only difference lies in a bit different laser form allowing both reading and writing. Besides, we should note that it's possible to combine WORM and ROM on one storage device! For example, imagine a 20-layer disc with 10 layers already recorded and 10 left for a user. The company C-3d also plans to release rewritable FM discs (in the end of 2001). The record principle is practically the same as in CD-RW technology except for the fact that there it isn't necessary to control reflective ability of a layer - there is enough to convert fluorescent material from one state (absence of fluorescence) into the other (presence of fluorescence). For example, the whole layer of a FM disc will be covered with a fluorescent material which initially doesn't possess fluorescent properties (logical zero) and when recording a logical one a low-power laser excites a photochemical reaction in the required place. Erasure will be done with the help of a more powerful laser. An advantage of this technology is that the fluorescent material is much more resistant to phase transformations than that used in CD-RW discs that's why you can rewrite it much more times. Parallel readingAs we have already mentioned this technology allows parallel reading; it means that a sequence of bits is recorded not along a track but deep into layers. That's why we receive three types of data reading: successive, successive-parallel and parallel. A little about what in fact parallel reading is. Reading process is carried out with the help of a solar cell (an array of CDD cameras). This device can read low-power fluorescence of several tens MHz. And the reading speed reaches 1 Gbit/s. We should notice that mechanical speed of the drive is 450 times lower than that of DVD. Below you can see pictures from the site of the company C3D which clearly demonstrates the principle of operation of parallel reading.  FMD fragment  12x enlargement of FMD segment received with CDD cameras  Signals received from each element of CDD array Some words on other products of C3D companyBeside FM discs the company has another product called FMC ClearCard ROM. This is a device for data storage sized a credit card. Inside there is a FM disc 50 mm in diameter. The first models of this device will keep up to 10 GBytes in 20 layers with 400 MBytes/cm2 record density. Prime cost of this product will be less than $10. It's considered to be a good substitute for current flash-cards in many spheres. The FMC read devices are not big and requires little power.  Besides, the company states that in their laboratory they ha received a disc with 50 layers, capacity of 1 Tbyte and up to 1 GBytes/s data rate. ConclusionWell, the only I can say here is that these products will be the roughest competitors to CD and DVD. The company C3D plans to release its first products

already in the end of 2000. We don't know anything about prices,

and today it's difficult to say when it will enter in mass sales

market.

Write a comment below. No registration needed!

|

Platform · Video · Multimedia · Mobile · Other || About us & Privacy policy · Twitter · Facebook Copyright © Byrds Research & Publishing, Ltd., 1997–2011. All rights reserved. |